2021-07-08

LEAD CHEMICALS adhesive systems are used in the manufacture and assembly of components across a diverse range of industrial sectors.

From transport and hygiene to food labeling and packaging, we partner with customers in manufacturing to innovate smarter adhesives.

Our technologies make your products lighter, safer and more durable. But our expertise goes beyond developing high-performing, multi-purpose adhesives. We improve your production processes with time and cost-saving solutions, making your operations more efficient, competitive and sustainable.

Choose your market

Our extensive experience in industry means we’re perfectly placed to understand the unique challenges of your sector. Find out more about the manufacturing markets we operate in:

Automotive Adhesive: Discover our award-winning bonding solutions for automotive interiors and exteriors.

Tape Adhesive: Discover our aesthetic, durable and versatile adhesive solutions for tape suppliers.

Labeling Adhesive: Make your products look their best with our adhesives for bottle labels and clear labels.

Medical Adhesive: Adhesives for medical applications including surgical drapes, transdermal drug delivery systems and wound care. Here our solutions offer direct skin contact, sterilization and fluid-resistance properties.

Flexible Packaging Adhesive: We partner with food manufactures and medical packaging specialists to innovate new flexible packaging technologies.

Rigid Packaging Adhesive: Maximize manufacturing efficiencies with our products for case and carton forming.

Disposable Hygiene Adhesive: we’ve rich experience in creating smart adhesives for disposable hygiene products.

Security & Couriers Systems Adhesive :Can be used as the security and express industry tamper-proof labels and adhesive tapes or security pouches for valuables.

Added value bonding solutions

We partner with manufacturers to create customized adhesive solutions, improving your performance and cost control

Manufacturing Efficiency

Achieve cost-in-use benefits through time, material and energy savings, minimize pre-treatment and eliminate unnecessary production stages.

Technical And Process Support

Get expert support from our technical team. LEAD CHEMICALS engineers work directly with our customers to improve operating efficiency and reduce production time and costs.

Sustainability

Take a greener approach to bonding. We are dedicated to offering durable and sustainable solutions that are free of VOCs and isocyanates.

Automotive Adhesive

We understand that creating tapes which achieve strong, long-lasting adhesion to low surface energy materials can be difficult. That’s why we’ve committed to using our advanced knowledge of chemistry, along with our technological expertise, in the formulation of strong, smart and effective automotive tape adhesives.

By offering a more efficient, cost-effective, and lightweight alternative to traditional methods of mechanical fastening or bolting, our automotive adhesives ensure that your tape can effectively bond body panels, wire harnessing tapes and be used for general gasket bonding and seals.

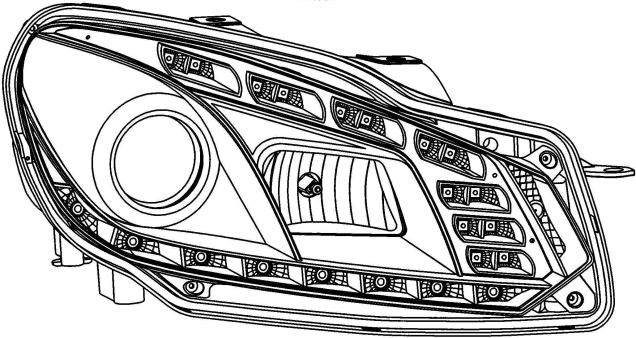

Encompassing headliner adhesive, body panel adhesive, trim adhesives, windscreen bonding and anti flutter adhesives, our range of automotive products are designed to enhance your product performance and improve operational efficiencies.

And whatever the interior or exterior application, our technical teams are on hand to meet your specific challenge – whether it’s about achieving lower costs-per-part or lower VOCs.

Smart innovations

Innovative and unique formulations like our hot melt pressure sensitive adhesive (HMPSA) are revolutionizing the way automotive manufacturers assemble their vehicles.

There are many more LEAD CHEMICALS smart adhesives to discover, from sound-damping innovations to superior creep test performers.

Automotive Headliners

There are normal headliners and sun proof headliners. The substrates for these applications can be non-woven, sheet metal, wool, foam, electric cord, and ABS.

Our Eco friendly hot melt adhesives satisfy the demands of bonding, lamination and fixation.

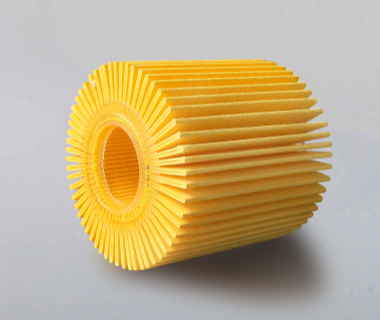

Oil Filter Adhesive

Oil filter applications include auto engine oil filter, scooter engine oil filter, and auto ignition system filter.

Besides the pleating glue and frame assembly glue, cap sealing and filter paper positioning are also the important applications of oil filters. Eco-friendly hot melt adhesives are most suitable grades for these due to good oil resistance and heat resistance.

Air Filter Adhesive

We tailor suitable hot melt adhesives for filters on the basis of production speeds, pleat numbers, and filtration media, which could be glass fiber, PET, PTFE, PP, paper, etc… We make sure the distance between each pleat is fixed, satisfy the demands of heat resistance & cold resistance, and offer good bonding strength, low shrinkage rate, which will not allow product deformation.

Hot melt adhesives assist filter shaping, and can be applied on filter pleating, filter, assembly, cap fixing and bonding, hollow fiber stuffing, bonding two sides of filtration media, bag stitched, and sealing of stitched holes.

The major applications of automotive lamps are assemblies of head lamp, tail lamp and fog lamp. We offer Polyolefin based, Rubber based and PUR based hot melt adhesives respectively for different operation demands.

Automotive adhesive application

Automotive adhesive application

Interior applications

Headliner adhesive

Body panel adhesive

Interior trim adhesive

Upholstery and Carpet adhesive

Tape Adhesive

Our hot melt adhesives provide efficient and reliable bonding for speciality tapes used for fastening, mounting and sealing.

We work with tape manufactures and converters in the medical, construction and automotive industries to develop adhesives that achieve exacting performance requirements. We also partner with manufacturers in electronics, electrical, paper printing, hygiene and white goods.

Our solutions work perfectly across a diverse range of carrier substrates and release liners, offering ease of converting and assembly as well as consistent quality.

Automotive Tape Adhesive

LEAD CHEMICALS adhesives are used for automotive tape applications including the interior and exterior fastening of panels, trims, carpet and badges. Our solutions help reduce vehicle weight, vibration and noise reflection.

Construction Tape Adhesive

Our construction tape adhesives are used for building applications including joining and sealing and carpet fixing.

Hot melt pressure sensitive technology

HMPSA is our key technology for speciality tape adhesives. LEAD CHEMICALS hot melt solutions are solvent-free and exhibit excellent tack, peel and adhesion even on low surface energy materials. More on HMPSA

Applications:

Assembly tapes for the automotive industry

Insulating and sealing tapes for the construction industry

Closure tapes: permanent or resealable

Tamper-proof closures for security pouches

Sterilizable medical packaging

FDA grades for food packaging

We offer a comprehensive portfolio of hot melt pressure sensitive solutions for general purpose and speciality labels. LEAD CHEMICALS label adhesives are specially designed to improve the efficiency of application processes while delivering an aesthetically appealing finish.

We work with most food suppliers, cosmetic specialists and breweries to produce sophisticated labeling adhesives with excellent processability and holding power.

From clear waterproof labels for health, beauty and care products to beer bottle labels, our smart adhesives are found in a wide range of specialist applications.

Smart innovations in label adhesive

We provide a comprehensive range of products for both permanent and removable label formulations. As well as possessing excellent tolerance of high and low temperatures (ranging as cold as deep-freeze conditions), our label solutions also boast excellent holding power, clarity and adhesion to low surface energy substrates, while accommodating high line speed and ensuring clean die-cutting.

LEAD CHEMICALS has the right solution for every challenge: permanent, easy to remove, repositionable and removable without leaving a residue. Depending on the application, you will find the right adhesive for your labels.

Contact us if you wish to enquire about bespoke formulations for your own labeling needs.

Applications:

• Address labels

• Business forms / mailing systems

• Direct food contact

• EDP labels

• Functional labels

• Labels for frozen products

• Clear-on-clear (highly transparent)

• pricing / product labeling

• Security labels

Smart adhesives for long-lasting and legible tire label adhesion

We supply customers throughout the entire tire label supply chain - be they in the production, conversion, printing or application of labels. We’re committed to supplying the adhesives our customers need for tire labels that are clear and legible with a sleek finish, and that can bear the brunt of extreme storage and transportation conditions.

Having specialized in smart and durable adhesive technologies more than ten years, our knowledgeable research and development teams are equipped to provide tire labels with the strong, smart adhesions and chemical properties our customers demand.

Tire labels: adhesive applications

The adhesive products we engineer to be compatible with vehicle tire labels are formulated to provide exceptional grab and a tenacious bond. Not only that, but their polyvalent properties provide exceptional long term adhesion and gap-fill over all kinds of irregular surfaces and face materials.

We are constantly adapting our chemical engineering processes to optimize the productivity of our end users. That is why our tire label adhesives consistently provide excellent die-cutting capabilities, even at a high coating weight.

Our adhesive solutions ensure that the most important information on tire labels is flawlessly clear – from load indexes, to temperature grades and tire traction specifications.

Repeated mechanical and load stresses, extended inventory duration, and extreme temperatures are no match for our tough label adhesives. Our tire-specific products are also fabricated with coarse, oily surfaces in mind, so by choosing an our product, you can rest assured the sprues on new tires won’t hinder our adhesive’s ability to stick labels down.

For bespoke adhesive solutions tailored to your specifications, contact our technical support team to discuss one-off formulations.

Tire labels: adhesive technologies

Hot melt pressure sensitive adhesive (HMPSA)

We produce ranges of our market-leading hot melt pressure sensitive adhesives designed specifically for use by labeling manufacturers. Our unique, patented HMPSA solutions are specially engineered to maintain consistent, high-level performance.

Even if your tires are fresh from the molding line, our HMPSAs will still hold the labels on your tire, regardless of their temperature.

Deep freeze label adhesives for the frozen food packaging industry

We know that clarity of labeling is of the utmost importance in the food industry. That is why our deep freeze adhesive products are engineered to ensure the packaging and labeling of your products maintain an unflawed, legible appearance and are easily traceable as a result.

We work with a wide range of customers across the frozen food and food grade packaging supply chain and are continuously adapting our engineering and research processes to supply the market with reliable, durable, and sanitary solutions for cold storage labels.

Deep freeze labels: adhesive applications

Our versatile range of deep freeze label adhesives are chemically engineered to be compatible with the surface types commonly used with meat and fish products, as well as other typical packaging substrates - both refrigerator and freezer grade.

Your label bonds won’t be compromised by either cold or damp surfaces, or high degrees of condensation. Like all our label adhesives, LEAD CHEMICALS freezer grade products possess impressive die-cut abilities and provide easy convertibility to minimize curling, warping, or bleeding of your labels and their edges.

Debonding does not occur with our adhesives, granting you reliable, and cost effective labelling solutions. All our deep freeze label adhesives are formulated with the intent of providing superior manufacturing efficiency, and clean label application.

As well as ensuring minimal staining, easy machining, converting, and general processing, our adhesives can work to deep freeze temperatures as low as 15 degrees Fahrenheit, for both permanent and removable labels.

Deep freeze labels: adhesive technologies

Hot melt pressure sensitive adhesive (HMPSA)

Our strong and versatile hot melt pressure sensitive adhesives are suitable for a vast range of applications. Offering fast setting, short open times, and excellent wet out, our hot melts are engineered to provide you with cost-effective, productive, and robust adhesive solutions that minimize wastage and emissions.

Thorough research and testing are regularly carried out to ensure that our HMPSA products perform consistently in as many working and manufacturing environments as possible. Learn more about HMPSA for label »

For surgical gowns and drapes, wound care and direct skin contact

All of our adhesive products are specially formulated to achieve optimal performance with low cost-in-use, while maintaining the highest level of sanitary standards and environmental safety.

Our speciality medical tape adhesives are used in many applications including surgical drapes, incisive foils and the production of wound care and fixation tapes. They provide excellent resistance to surgical and bodily fluids and are made from hypoallergenic materials to ensure the highest standards of patient comfort.

Whether it's a sticking plaster or adhesive tape, the requirement remains the same: the product should stick for as long as desired and it should then be possible to remove it from the skin cleanly and painlessly. LEAD CHEMICALS hot melts for direct skin contact meet these requirements and also support the healing process.

Like a temporary skin.

LeCare™ low peel

LEAD CHEMICALS low peel adhesives minimize pain and negative impacts on the wound healing process through traumas. The self-adhesive wound dressing based on a non-curable acrylate hot melt is particularly suitable for sensitive skin. The adhesive has good initial adhesion and can be easily repositioned.

The sterilization properties in our range of medical tape formulations makes them perfectly suited for all medical environments and direct contact with the skin, as well as many other wound care applications.

Applications

Hot melts for direct skin contact

Medical plasters

Self-adhesive finishes for surgical drapes

Low peel applications (alternative to silicone adhesives)

UV-curable hot melts -Hydrocolloids

Contact us for more information and read our information sheet on low peel adhesives »

Disposable Hygiene Adhesive

Smarter adhesives that do more

A smart adhesive is one that enables a disposable hygiene product to fulfill its mission: keep the wearer dry and comfortable…and be discrete about it. It also has the intelligence to enhance manufacturing operations by improving efficiencies, reducing costs and expanding adaptability.

As our customers encounter new challenges – thinner cores, better absorption, improved softness, and changing substrates – we are ready with smart solutions to ensure uniform performance and production.

Through innovation and collaboration, Our product development team has the depth of experience necessary to ensure superior bonding and overall performance. And because our dedicated market experts keep a close eye on emerging trends and dynamics, we will help you be ready to meet them successfully. When you have a new idea or are beginning a project, it is time to contact us.

Contact us for more information and read our information sheet on disposable hygiene adhesive »

Packaging Adhesive

High-quality adhesives for the packaging industry

Hot melts developed especially for the packaging industry guarantee secure adhesion, even when faced with the highest demands.LEAD CHEMICALS has the right adhesive for any packaging material to guarantee secure packaging.

Adhesives for demanding applications in the packaging industry.

If additional protection and security functions are required, we have the right solution - or can develop one for you. Thanks to the advanced technology behind LEAD CHEMICALS hot melts, we get to grips with even the toughest packaging demands: quiet opening, resealable, odourless and tasteless, sterilizable and tamper-proof. Contact us for more information »

Flexible Packaging Adhesive

A complete range of high performance and innovative flexible packaging solutions to meet your storage, transportation, marketing and productivity needs.Our customized solutions provide you with cutting edge packaging technology to meet the most demanding packaging applications.

Smart innovations

We partner with food manufacturers, medical packaging professionals and other industrial innovators to develop the fast-curing, environmentally-friendly products that define modern flexible packaging. From medical packaging to specific food packaging implementations, such as cheese and meat packaging.

Discover our extensive range of flexible packaging Smart Adhesives, from solvent-free adhesives for food packaging, to high-performance polyester materials for industrial applications.

Contact us for more information and read our information sheet on packaging industry adhesive »

Security & Couriers System Adhesive

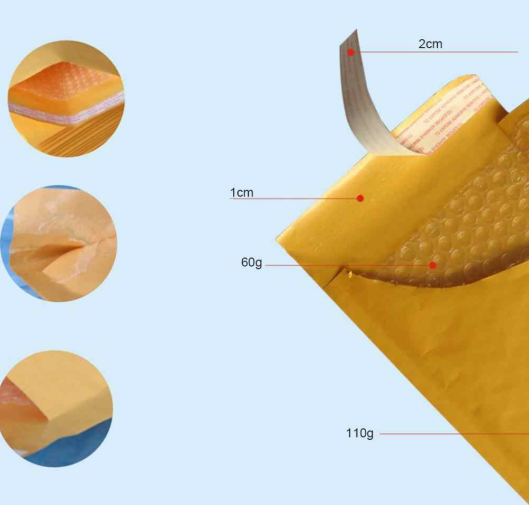

LEAD CHEMICALS adhesives impress not only through their outstanding adhesive characteristics. Thanks to the latest developments, Our hot melts can be used as security systems for tamper-proof labels and adhesive tapes or security pouches for valuables.

Adhesive as a security system - a case.

Intelligent adhesives assume security functions. They make attempts to tamper with packaging visible or provide different colors to protect against confusion. Our adhesives also provide brand protection and highlight imitations through integrated security features. What challenges does your product face?

Applications

• Tamper-proof labels

• Tamper-proof tapes

• Security pouches for valuables

• Transport and storage

Contact us - together we'll find the best solution. »

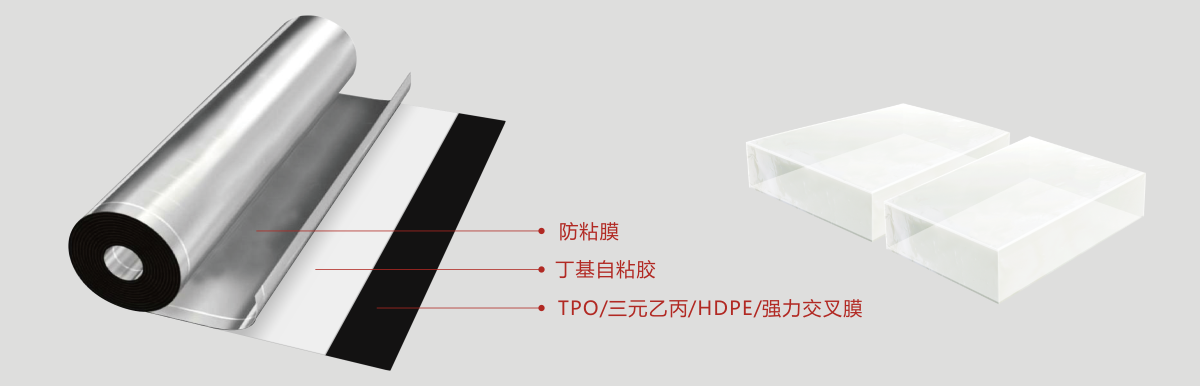

Resistant adhesive for the construction industry

Hot melts for the construction industry must be particularly resistant and meet the high requirements of the field of application. LEAD CHEMICALS hot melt solutions can be used for insulating and sealing tapes, laminating adhesives for roofing underlays, impact sound insulation or bonded insulation panels.

LEAD CHEMICALS adhesives are used in the construction industry as solid and 100% environmentally-friendly systems. We colour our products to meet your demands. We have a special focus on adhesives that are not readily flammable, so-called flame-retardant adhesives.

Contact us for further information »