2021-09-28

Petroleum resin is a kind of thermoplastic resin produced by cracking C5 olefins in the by-product of ethylene plant through pretreatment, polymerization,Petroleum Resin flash evaporation and other processes. It is an oligomer with a relative molecular mass ranging from 300 to 3000. Petroleum resin has insoluble in water,Petroleum Resin easily soluble in organic solvents,Petroleum Resin acid resistance, alkali resistance, water resistance,Petroleum Resin chemical resistance,Petroleum Resin anti-aging and other excellent properties.

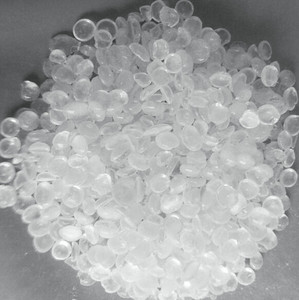

C5 petroleum resin has low production cost and large application. It can be made into blocks and granules and used as a tackifier in pressure-sensitive adhesives. Hot melt adhesive is a kind of adhesive that is melted by heating to produce fluidity,Petroleum Resin coated on the object to be bonded,Petroleum Resin and solidified after cooling. It is an industrial adhesive and has a wide range of applications, including carton seals for food, beverages and beer Boxes;Petroleum Resin carpentry furniture; wireless binding of books; labels, tape; cigarette filter sticks; clothing, adhesive lining, and cables, automobiles,Petroleum Resin refrigerators, shoemaking, etc.

The hot melt adhesive must be matched with a tackifier in order to bond firmly. In the past,Petroleum Resin natural resins such as rosin resins or terpene resins were used as tackifiers,Petroleum Resin but the prices were higher and the sources were unstable. In recent years, the use of petroleum resin as a tackifier has gradually become dominant.