2021-11-04

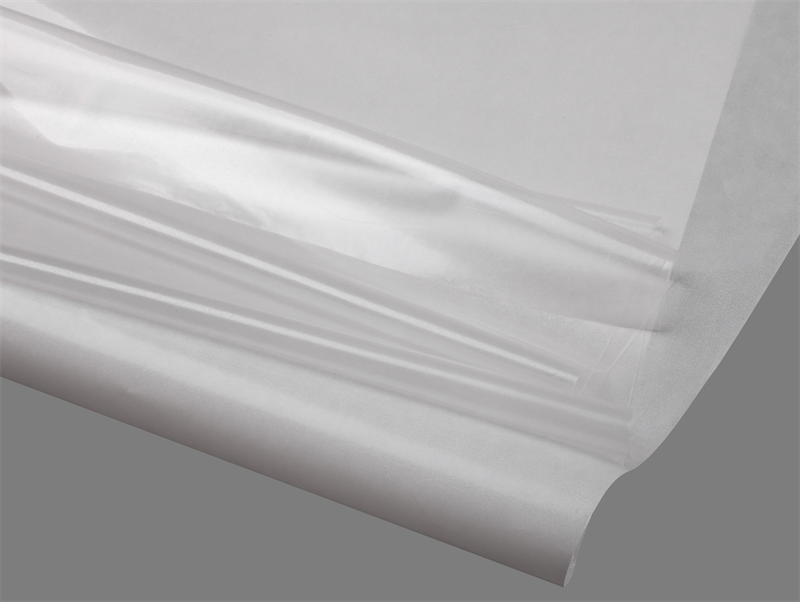

Hot melt mesh film is a kind of hot melt adhesive product with the appearance of mesh, similar to non-woven fabric. It has the inherent characteristics of hot melt adhesive, which is solid at room temperature and sticky after heating. It is packaged in rolls and can be used for continuous laminating operations, and is widely used for bonding various materials in the apparel and automotive fields.

1. Production process of hot melt film

Hot melt film is produced by melting the hot melt adhesive particles, and then the melted hot melt adhesive is sprayed and knotted by the equipment, and then cooled and wound. Different types of hot melt adhesive particles are used for different hot melt film products.

2. Hot melt film classification

Hot melt film is classified according to its composition: PA hot melt film, PES hot melt film, EVA hot melt film, TPU hot melt film, the physical properties of different components of hot melt film are different, so the application areas and applicable materials are also different.

3. Hot melt film characteristics

The characteristic of hot melt film is that it has good air permeability. Because it is made by spraying silk knotting process into the shape of the mesh, so after the glue melts, there are still gaps between the adhesive layer of the bonded material, which makes the hot melt adhesive film in the bonded material can maintain the original breathable performance of the material.

In addition, the hot melt adhesive mesh film has a better feel for the fabric when laminated. This is due to the production process of hot melt film. The unique spraying process makes the hot melt mesh film lower in gram weight, which means it contains less glue per square meter, so that the feel of the material is not affected too much when it is laminated.

4. Hot melt film specifications

In addition to the different materials, there are also different grammages and widths and lengths per roll.

In terms of grammage, there are 12g, 15g, 25g, 40g, 60g, etc. The weight per square meter is 12g, 15g, 25g, 40g and 60g respectively, which is commonly used for 25g hot melt film, and the grammage is customizable. For example, EVA hot melt film is generally 15-80g, while PA hot melt film is 8-120g.

From the perspective of width, the conventional hot melt film widths are mainly 1m and 1.5m, and the conventional specifications in slitting hot melt film are 1cm and 2cm, which are also customizable according to customer needs.

In addition, the length of each roll is determined by the grammage of the hot melt film. For example, 25g hot melt film is usually 500m per roll, while 12g hot melt film can be 1000m per roll. The thicker the gram of hot melt film, the smaller the number of meters per roll.

5. Hot melt film and double-sided adhesive liner

Is hot melt mesh and double-sided adhesive lining the same thing? In the garment industry, hot melt adhesive mesh film has been called double-sided adhesive lining, hot melt ironing lining, etc., in fact, said the same product. It's just that in different industries, hot melt films are used for different purposes, and the industry is used to calling the products they use according to their purpose. In the apparel industry, hot melt film is often used to bond fabric and lining, so it is rightly called double-sided adhesive lining.